Main usage :

Outdoor consturction's decoration, transforr iation in old exterior projects

Product' advantages:

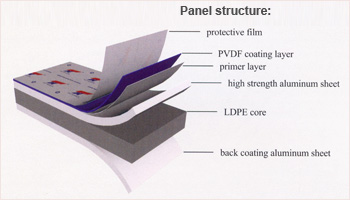

1).Super weather ability The PVDF coating is based in HYLR5000 & KYNAR500 has special advantage in corrosion resistance, pollution resistance and weather resistance,the products can keep best appearance even under extremely hot i r frigid weather.

2). High peel strength Peel strength is the key technical index forACP. The introduction of the U.S.A Dopont technology and raw materials has made Sky a National Top level. We have exceed 50% of national standard. Meantime improving the sheet's platness.

3). Impact resistance We use the Dopont Adhesive film, the FULLSUN and JINCHAOYANG paints,southwest aluminum alloy, after high temperature lamination, the product has best performance in impact resistance, strength and T-bend characteristics. It can keep good shape even in wind-blown-sand climate.

4). Evenly coating and customized colour We have our own stable quality control system and imported chemical and coat-

ing lines, the use of chemical treatment and oxidative foils technology applied in alloy surface, can give strongly adhesive force between alloy and the coating layers. Supply evenly thickness. Customer has more colour choices. |